Special promotions are available! Don't miss out on great deals!

Sandblasting cabinet 520l, with dust extractor

Product code: SBC520E

Brand: Lincos

Blasting cabinet size 1200x700x650mm, lighting, cyclone tank, large front door, side doors, pedal-controlled blasting gun, max. 8.5bar, air consumption 400-700l/min

Sandblasting cabinet 520l, with dust extractor

Sandblasting cabinet 520l, with dust extractor

Sandblasting cabinet 520l, with dust extractor

Sandblasting cabinet 520l, with dust extractor

Sandblasting cabinet 520l, with dust extractor

Sandblasting cabinet 520l, with dust extractor

Sandblasting cabinet 520l, with dust extractor

Sandblasting cabinet 520l, with dust extractor

Sandblasting cabinet 520l, with dust extractor

Sandblasting cabinet 520l, with dust extractor

Product description

Description

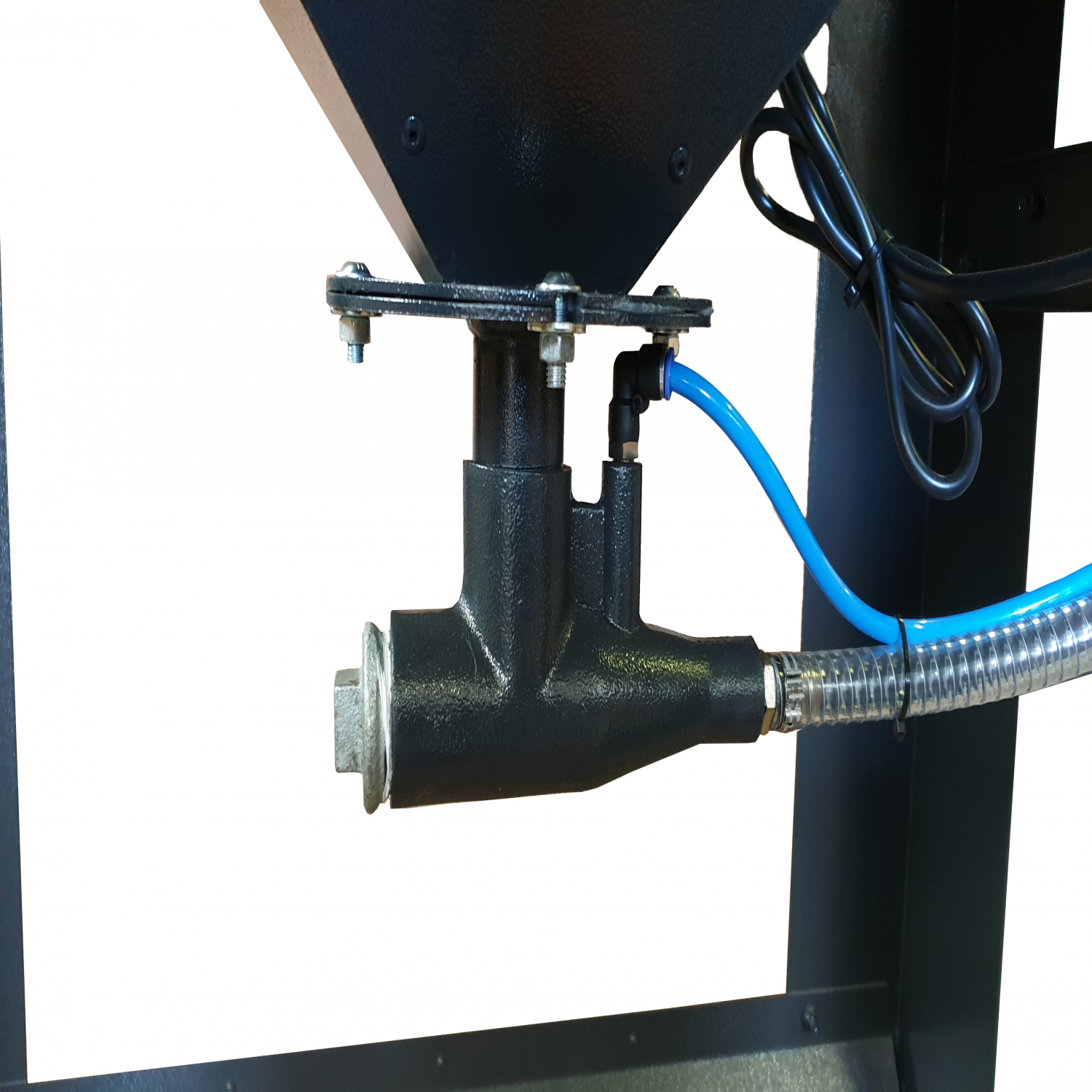

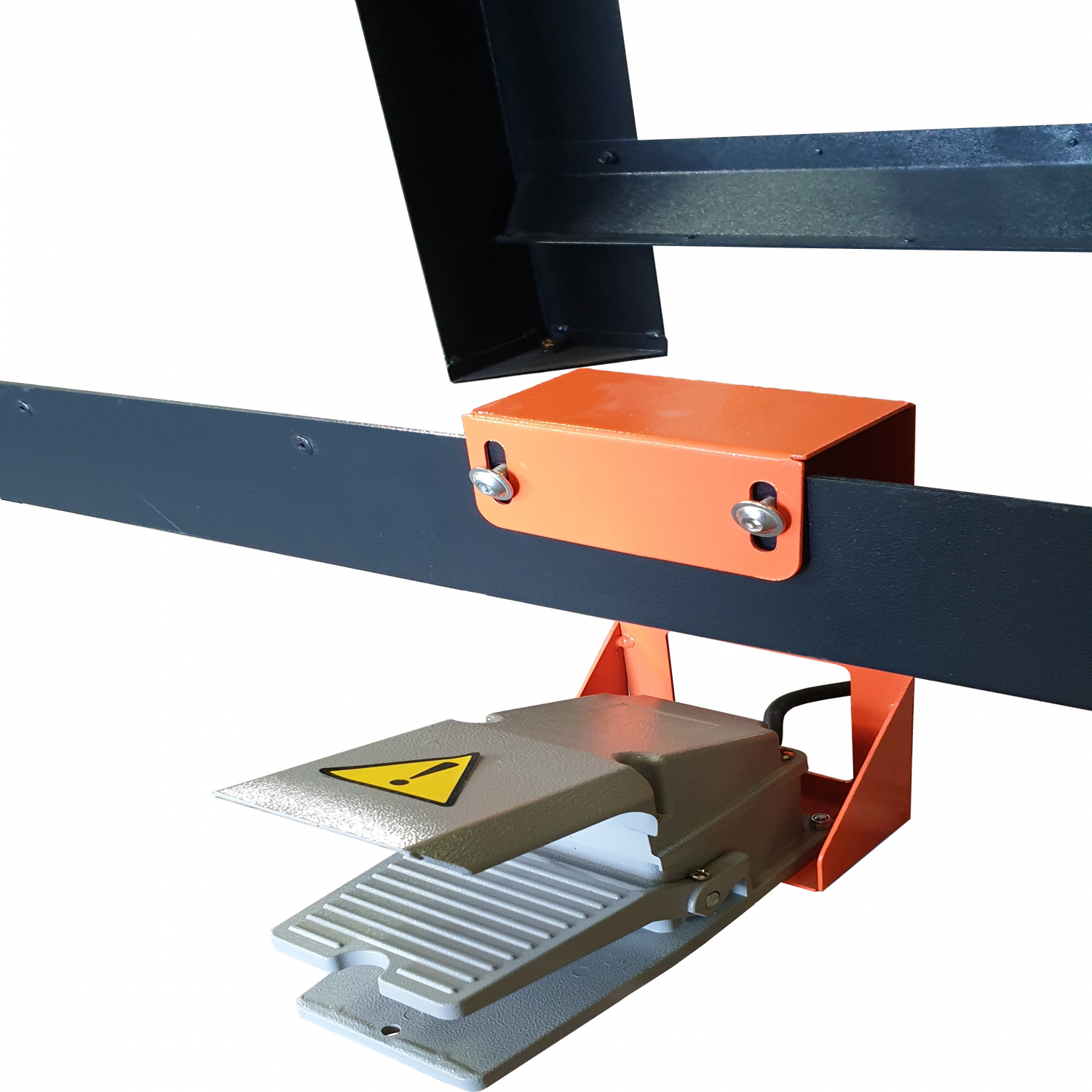

- Pedal-controlled blasting gun

- Flexible hose, built into the blasting cabinet

- Large sized window

- Large front door

- The cyclone assures the continuous extraction of the dust and the sand

- Inner lighting

- Doors on both sides (230x240mm)

- Surface treatment powder coating

Technical details

| Blasting cabinet size | 1200x700x650mm |

| Total size | 1260x770x1740mm |

| Cyclone size | 420x410x1110mm |

| Cabinet volume | 520l |

| Cabinet volume with sand tank | 700l |

| Side door size | 230x240mm |

| Front door size | 1260x700mm |

| Max. pressure | 8,5bar |

| Operating pressure | 3,4-5,5bar |

| Air consumption | 400-700l/min |

| Gloves length | 600mm |

| Gloves diameter | 160mm |

| Tank capacity | 18kg |

| Power supply | 230V, 50Hz |

| Cyclone power consumption | 1200W |

| Lighting | 50W (23V) LED, IP67, 5000lm, -40°C - +55°C |

| Noise level | 80dB |

Accessories

- 5 ceramic nozzles (3pcs 6mm, 2pcs 7mm)

- 1 sand blasting gun (industrial)

- 2 window underlays

- Cyclone tank

- Control pedal

- Electrical control panel: emergency stop, lamp, cyclone switch

- 1 water-separator/regulator

- Sand mixing valve

- Door solenoid valve

- Support bar for hanging small items

Abrasive media used

- The quality of the media used for polishing influences the effectivity of blasting.

- Ordinary sand may contain contaminants, which may cause the machine to malfunction.

- Moisture and organic matter contained in the abrasive media may clog up the nozzles and the valves.

- If the abrasive media is used repeatedly, the reduction of the particle surface must be considered, which reduces the effectivity of the blasting process.

- Quartz sand, glass beads, polishing dust, synthetic sand

Product packing

| Pack number | Dimensions | Weight |

|---|---|---|

| 1 | 127 x 80 x 194 cm | 152 kg |

Delivery fee

| Delivery method | Net price |

|---|---|

| Pickup in Nagytarcsa | 0,00 € |

| Pickup in Debrecen | 0,00 € |